With the ability to leverage an alternative equipment maintenance (AEM) program, healthcare technology management teams (HTM) can build maintenance protocols that increase operational efficiency while keeping patient care and safety in the forefront.

An effective AEM program starts with risk management to understand which equipment would benefit from alternate maintenance protocols. And, with the ability to leverage data from a computerized maintenance management system (CMMS), these decisions need to be evidence based, fully documented, and measurable.

From determining which assets qualify to be put onto an AEM, to monitoring the AEMs’ impact on device performance, a comprehensive CMMS can provide essential insight into what’s working – and how to continue to deliver improvements.

What is an AEM Program?

The Centers for Medicare and Medicaid Services (CMS) give hospital and healthcare leaders the option to create a maintenance program for equipment outside of what the manufacturer recommended. This stems from issues that arise with older equipment, where teams may not have the original manuals or maintenance specifications in place.

Advances in technology, like using a CMMS to manage all work orders and maintenance tasks, brings the ability for HTM teams to focus on building a risk-based approach. This means that equipment receives service based on key measures, which may include:

- Equipment criticality

- Usage frequency

- Environmental conditions

- Historical performance data

This information then feeds into a maintenance schedule to understand when the equipment should be maintained. Building a maintenance schedule based on real-time conditions offers several benefits.

At the core, it starts with improving resourcing. After all, resource management continues to be an area of focus for HTM teams. From limited budgets and smaller teams, asset management leaders face challenges with doing more with less. But, with the right technology in place, it can transform how work gets done. In some cases, this can mean doing less with less.

Less with less? Yes! The art of using technology to automate and handle many manual tasks, which can be time consuming for team members. In doing so, teams can let the technology do this work for them so they can focus on where it matters most.

How does this approach impact an AEM program? The CMMS can become the place where all information lives to build effective models to assess risk – identifying which equipment would benefit from alternative maintenance schedules. In doing so, it can help to minimize unnecessary maintenance procedures and protocols. This means essential resources are spending time where it matters most – without reducing uptime.

In addition, this data can inform what maintenance should occur and when. Focusing more on preventative – and even predictive – maintenance can improve overall functioning of equipment and respond to issues before they become significant issues.

To get to this point, it requires starting with clean and comprehensive data. This helps to inform risk assessments and build models to understand which equipment will benefit from an AEM program.

Scoring Models for Alternative Equipment Maintenance

Identifying, analyzing, and evaluating potential issues with equipment serves as the first step in setting up an AEM program. This helps to identify which equipment may benefit from a more flexible maintenance schedule.

Critical equipment will continue to require stringent maintenance (like ventilators or anesthesia machines), while general use or basic patient care items may benefit from alternative maintenance protocols.

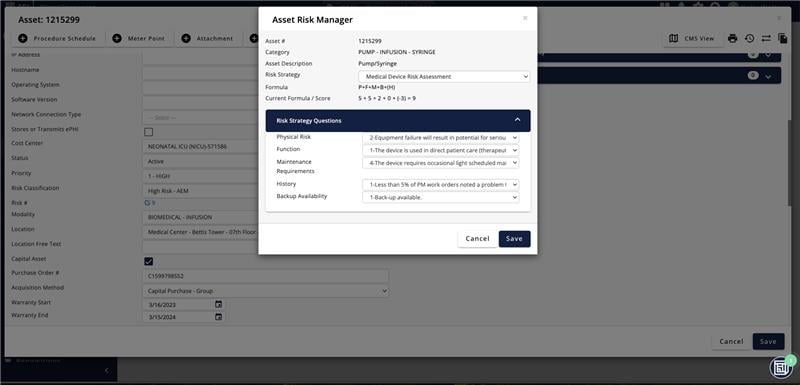

In building a risk assessment to score whether equipment should be put into an AEM program, it requires a look at the data that exists in the CMMS.

Outside of how the equipment may be used, other factors should be considered to effectively evaluate risk. For instance, not all equipment types will benefit from an AEM program. For some, this type of program could drive up costs.

And of course, compliance and regulatory requirements continue to be a key consideration for an AEM program. Having the right documentation in place will demonstrate that equipment continued to receive ongoing maintenance to optimize performance. A CMMS can ensure that all data can be tracked and managed to compliance requirements.

Lastly, the risk assessment should identify whether the equipment needs to be maintained in a particular way to keep warranties in place. These warranties may require certain maintenance strategies, replacement schedules, or even part replacements. This should be considered in building an AEM program for the specific equipment.

With this in place, a scoring model will determine which equipment may benefit from an AEM program. Once identified, teams can build out the AEM program that makes the most sense given the equipment and maintenance needs.

Once again, technology plays a role to help minimize the effort required for teams to build out these alternative maintenance schedules. For instance, a modern CMMS solution that makes associating alternative equipment maintenance schedules to the appropriate parts of the inventory a straightforward endeavor. These automations can even generate follow up tasks given what may be uncovered during maintenance. This means that HTM teams can focus on getting the work done – and letting the system do the tedious, manual work that can be time consuming.

The Role of Data & Analytics to Measure Performance

As the industry continues to focus on data-driven decisions, much of this comes from the information that’s collected in the CMMS throughout the maintenance activities that are conducted as part of the AEM. (Having troubles getting all the required information recorded in a work order? This is where CMMS workflow automations can help!)

From maintenance logs to incident reports to sensor data, the CMMS becomes the single point of truth for all information related to equipment. Once these invaluable signals are housed within your CMMS, the solution needs to be able to put the data to work for you and your organization.

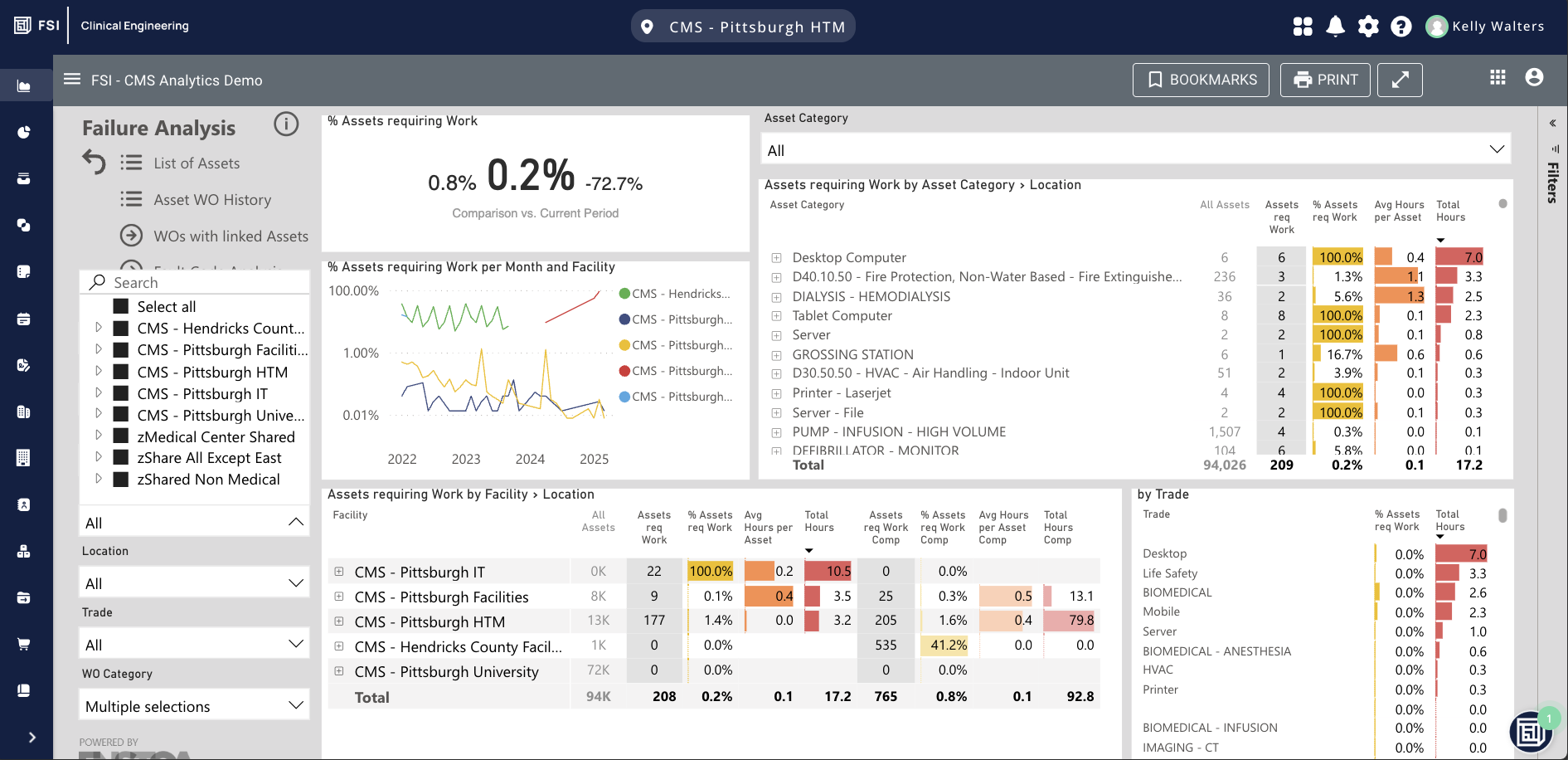

Looking at failure trend analysis can showcase how maintenance activities are impacting the overall performance of equipment; and give insight into whether Mean time between failure is increasing, or conversely, is the organization's AEM having a negative impact on device performance.

Key metrics can provide deeper insight into the AEM program, too. These include:

- Mean time between failures (MTBF)

- Mean time to repair (MTTR)

- Equipment uptime

- Maintenance costs

- Technician productivity

Within a CMMS like FSI, using dashboards can give a visual representation of what’s happening and key performance metrics that can help indicate success for the HTM team. These dashboards provide surface-level information, and the option to click into key metrics to understand what’s feeding the data.

When things are performing better than expected (or perhaps not going as planned), this deeper layer of insight can help inform critical decisions moving forward.

Lastly, once this data informs key metrics, this can feed into the risk assessment for the AEM program to further identify other equipment that could benefit from a flexible maintenance schedule. Using data to inform key actions means that flexibility – a key cornerstone of AEM programs – can be leveraged to ensure optimal operation for equipment between maintenance checks.

And, as noted previously, this data can do more than inform maintenance activities. It becomes the record that can be used for compliance and regulatory reporting. Documenting what’s happening and why throughout the AEM program can be important to demonstrate that maintenance activities have occurred, and that they are in compliance with key requirements.

Building an AEM program can offer many benefits to HTM teams, particularly as they look at ways of maximizing the people and budget that they have in today’s environment.

Using technology can simplify the entire process – from risk scoring to failure analysis – and give teams the tools they need to execute an alternative maintenance program that delivers wide-reaching benefits for the facility.

Interested in learning more about building an AEM program to maximize your team’s productivity? Tune into our webinar with AAMI on March 20! Register here.